Ready for RFID

For the production of microchips, the processes of semiconductor technology are applied in a specific sequence on a substrate. The substrate is usually a thin slice of a semiconductor single crystal (usually silicon), a so-called wafer.

Error-free control and complete monitoring of all production steps are essential for loss-free production. Well-known manufacturers in the chip industry rely on our RFID systems and their reliability in their production facilities.

The Task

The wafers go through a variety of chemical and optical process steps until they are turned into finished microchips. Each of these steps is associated with effort and costs, so that errors during the production process become increasingly expensive. The goal of a complete inspection of the materials before each process step is the prevention of errors and thus the avoidance of costs.

The implementation

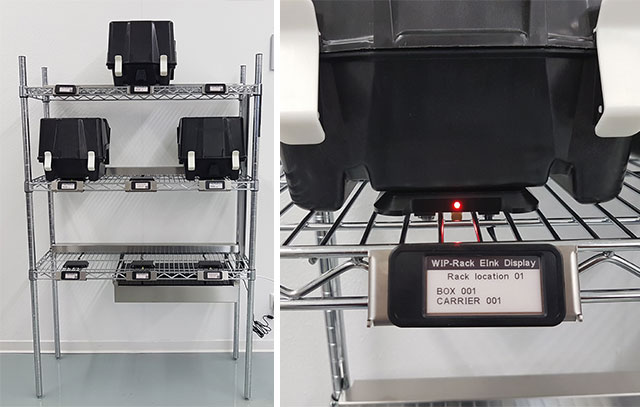

Each cassette is identified by a transponder that carries a unique identification number. Using this ID number, the cassettes are checked during the individual production steps and the information contained on the transponder is constantly compared with the specifications of the system.

Only if the data set matches does the cassette continue to run and the silicon wafers are processed one after the other. Has the specified life cycle of a cassette been exceeded? We can easily answer this important question with RFID technology. Our customer receives information about the age of the cassette, the number of process passes, and the number of cleaning steps at any time. Of course, he can also see which processes this particular cassette has undergone. Our control system thus secures our customer’s production line and helps to optimize processes, reduce throughput times and avoid incorrect processing.

In the development and production of our devices, we observe all requirements for use in clean rooms in the semiconductor industry. We deliver cleaned and cleanroom compatible packaged RFID components. Due to our many years of experience in the semiconductor industry, we offer customized solutions for a wide range of applications.

- Non-contact operation

- Identification directly at the production line

- Continuous checking of all production steps by automatic comparison with the database

- Monitoring of the life cycle of the production cassette